Carbon monoxide co oxides of nitrogen no 2 and no 3 ozone o 3 lead pb particulate matter pm both particulates with aerodynamic diameters below 10 micrometers pm 10 and particulates with aerodynamic diameters below 2 5 micrometers pm 2 5 sulfur dioxide so 2 and volatile organic compounds voc.

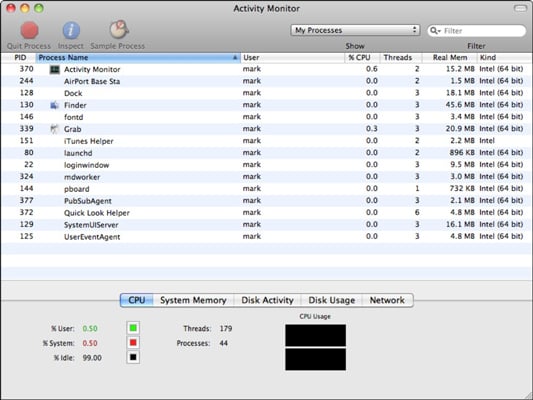

Air consumption monitoring.

It is a highly portable device with excellent efficiency.

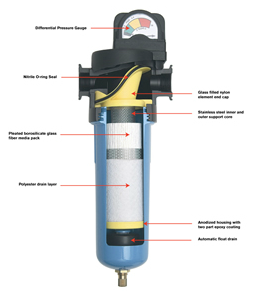

A monitoring solution for compressed air technical gases and energy management.

The purpose of estimating the air consumption of a cylinder is usually to find the horsepower capacity that must be available from the air compressor to operate the cylinder on a continuous cycling application.

This eve room indoor air quality monitor is a carefully designed air quality monitor.

Compressed air does not escape of this trend from the flow to the pressure measures that can help us detect leaks optimize the working pressure and have a history of the air consumed and the energy we spend to produce it.

Monitoring of compressed air consumption values is of major importance not least for efficient environmental management.

No wonder it.

The most basic is the ambient air monitoring program which collects national air quality data on criteria pollutants.

The author is available to answer questions.

The sensor will detect leakage areas based on the zone s increase in air consumption over time or monitor air consumption when machines in the zone are shut down.

In this section we ll discuss equipment and procedures that emergency responders can use to.

Run reports that include load unload starts usage costs and energy consumption.

Air monitoring is the only way to measure chemicals in these spaces.