The airframe mechanic major is certified under part 147 of the federal aviation regulations with an faa approved and supervised curriculum.

Aircraft sheet metal mechanic training.

This is relevant to all staff working in aircraft maintenance.

The training courses are split into three sections.

Adult students in the aircraft maintenance program are required to provide their own laptop set of tools and secured storage.

The aerostructure manufacturing and repair technology sheet metal structures certificate curriculum prepares individuals to fabricate manufacture assemble inspect test repair and manage the construction of aerostructures in an industrial setting.

Obligatory continuous training needed every two years.

Aircraft sheet metal mechanics fit and assemble parts of airplanes and space vehicles.

Upon completion of training the student will be able to assist experienced structures technicians in the aircraft line or base maintenance environment.

Entry level airframe mechanics as well as sheet metal workers belong to the target group of this training.

Perform sheet metal maintenance on rotor wing aircraft such as but not limited to reinforcing doublers stringers channels patches and replace defective structural aircraft parts.

Specific aircraft training for each kind of aircraft and 3 ongoing training.

Original aircraft components during practical training are used to increase the realism of the training and boost the.

Determines the nature and extent of repairs to be made using applicable technical manuals tms as guidelines.

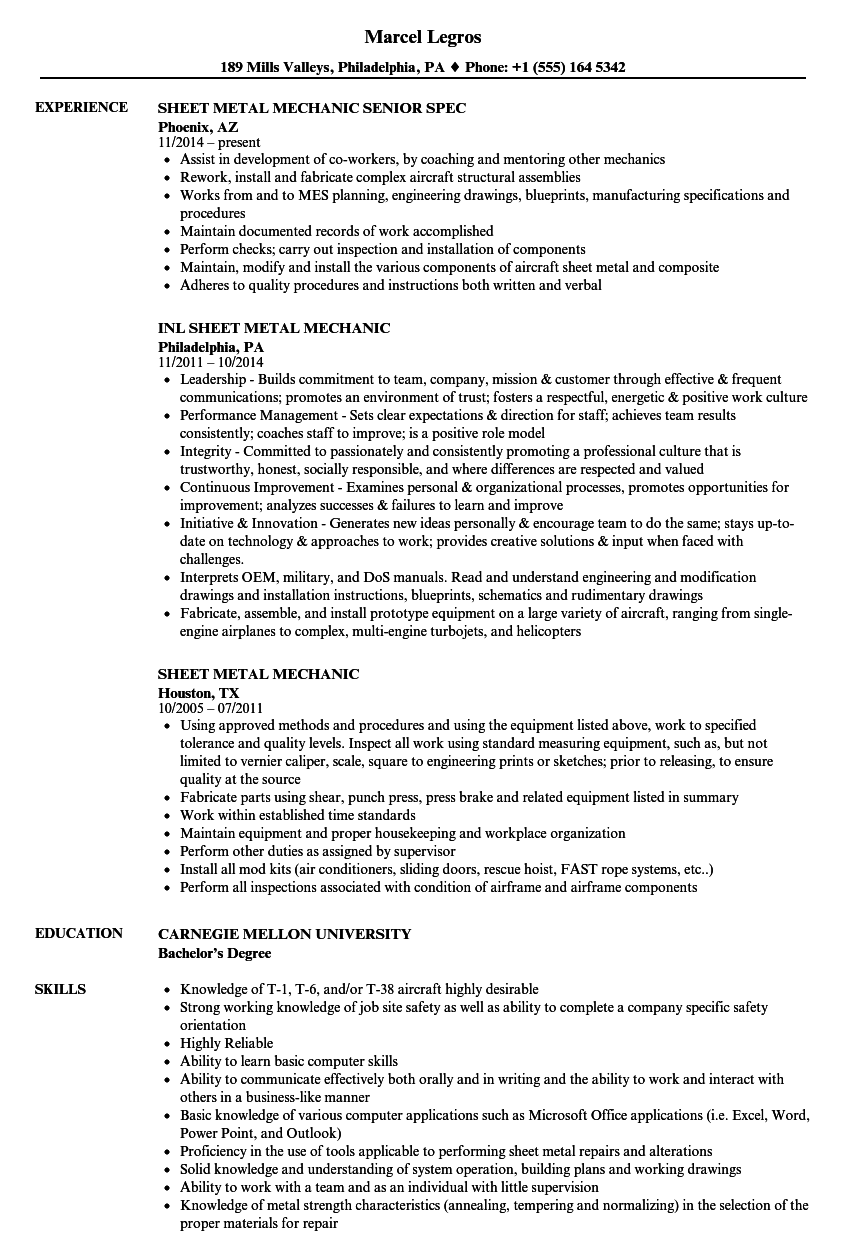

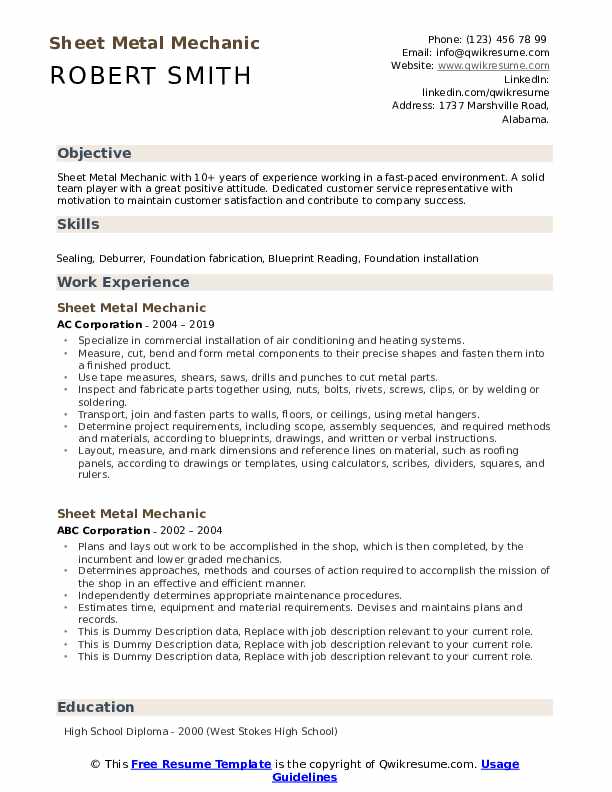

Typical duties listed on a resume sample for aircraft sheet metal mechanic include reading blueprints trimming parts maintaining system components inspecting and testing units verifying tension of cables and capturing waste materials.

Apply to sheet metal mechanic aircraft mechanic ii aircraft mechanic and more.

Inspects and troubleshoots aircraft structures such as fuselage tail wings cowlings and stabilizers.