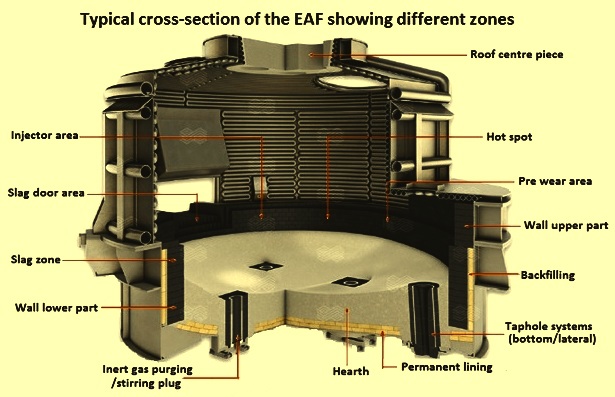

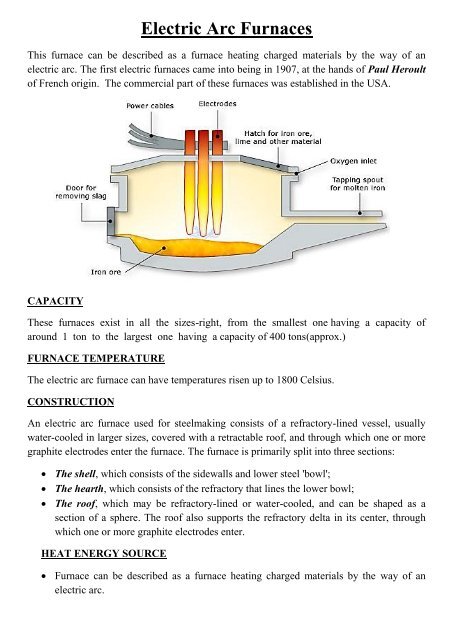

In electric arc furnace steelmaking the temperature of the slag is higher than that of the molten steel and the slag has a strong ability to participate in metallurgical reactions.

Advantages of electric arc furnace.

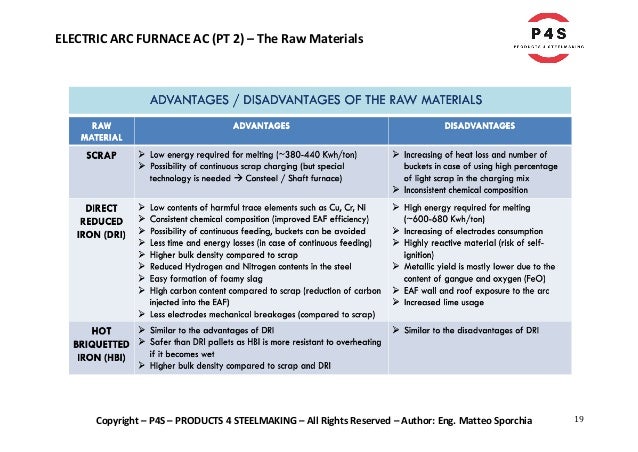

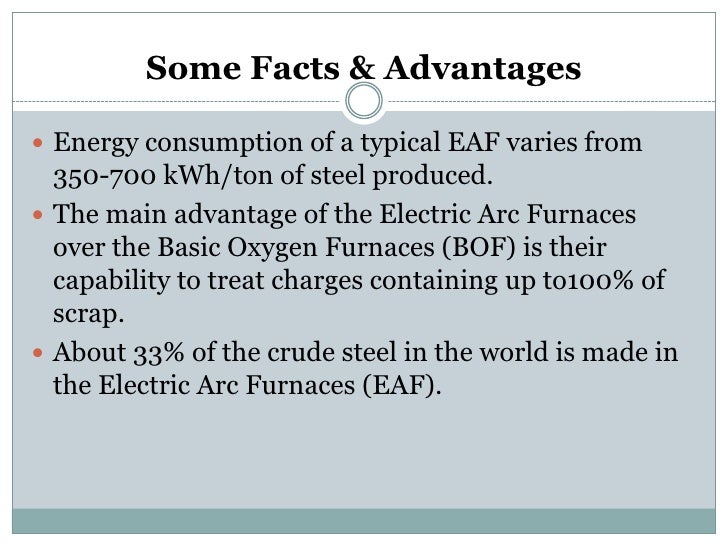

The first benefit is that the use of electric arc furnace allows steel to be made from a 100 scrap metal feedstock.

In the induction furnace the slag is heated by molten steel and the temperature is low so the ability to participate in the metallurgical reaction is weak.

The arc furnace can also smelt various kinds of different steels compared with others the arc furnace also has several obvious advantages.

The electric arc furnace is mostly accepted by steel making companies thus a large quantity of graphite electrode are consumed.

The arc furnace tends to be larger and more powerful.

Therefore in the induction furnace steelmaking the effects of metallurgical processes such as desulfurization dephosphorization and diffusion.

Electric furnaces require far less maintenance than gas furnaces.

Less investment quick to construct and fast cost recovery.

Because electric arc furnaces rely on mostly recycled materials to produce steel the environmental factors alone are considered a major advantage over the alternative.

These types of adjustments are simply impossible with sintering.

Using 100 percent recycled steel electric arc furnaces help contribute less waste material and saves on primary resources and energy while lowering greenhouse gas emissions.

This greatly reduces the energy required to make steel when compared with primary steelmaking from ores.

The advantages of buying an electric furnace.

A reduction of silica and certain amounts of titania in the bauxite also occur improving the alumina content from 80 85 in the raw material and up to 95 96 in the fused product.

This makes them the ideal choice for people who simply do not have the time or desire to maintain their heating system on a regular basis.

In electric arc furnace steelmaking the temperature of the slag is higher than that of the molten steel and the slag has a strong ability to participate in metallurgical reactions.

Melting of bauxite in an electric arc furnace in the presence of carbon results in a reduction of iron oxide to an iron metal and because it has a higher specific gravity when compared to alumina it moves to the furnace bottom.

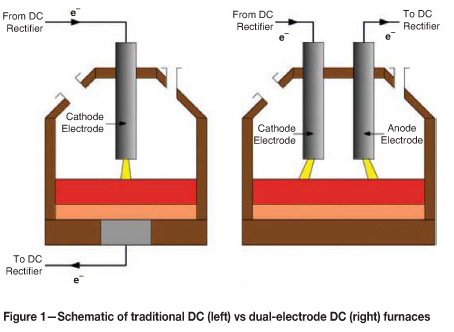

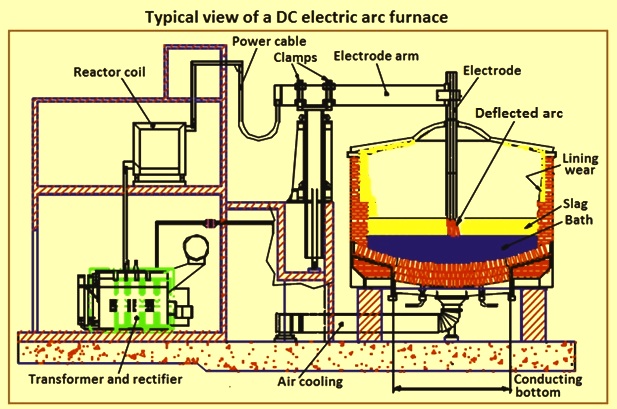

Theoretical analysis points out that the use of direct current instead of alternating current is a major technical innovation measure.

The supply and the price of electricity become stable which makes it possible to generalize the arc furnace.

2 the arc furnace could remove the toxic gases and the inclusions while deoxidizing and desulfurating.

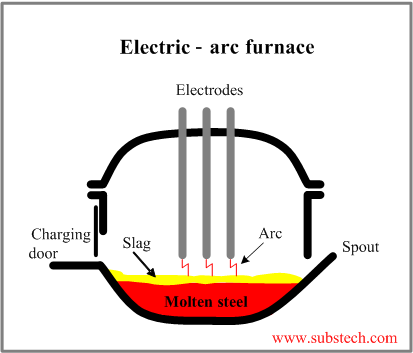

1 the arc furnace can heat the furnace and the steel up to 4000 6000 directly and smelt special steels that contain refractory elements like w and mo.

Advantages of dc electric arc furnace electrodes the dc arc is superior to the ac arc in terms of stability and unidirectionality which has great benefits for heat transfer in the metallurgical process.

This will also help to minimize the frequency of furnace repairs in the event that the required maintenance does go unattended for any period of time.

.jpg)