Advantages of electric arc furnace for steelmaking the electric arc furnace is mostly accepted by steel making companies thus a large quantity of graphite electrode are consumed.

Advantages of electric arc furnace for steelmaking.

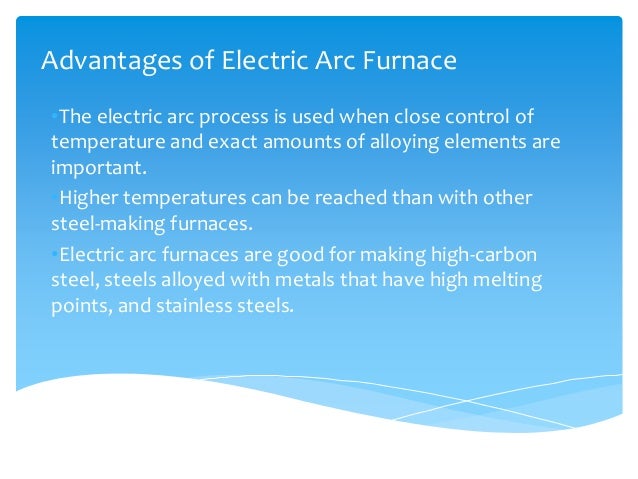

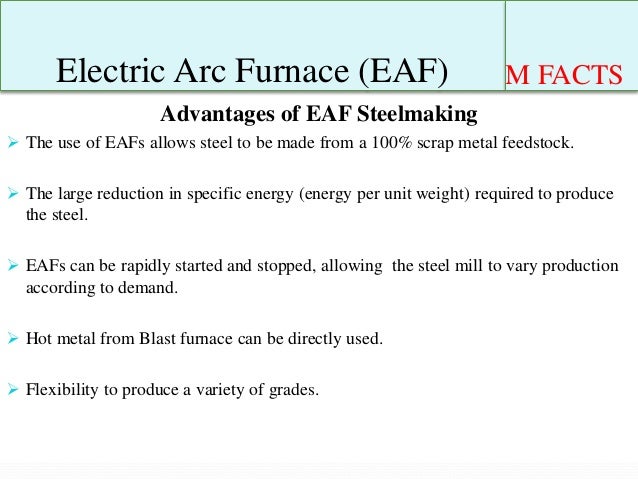

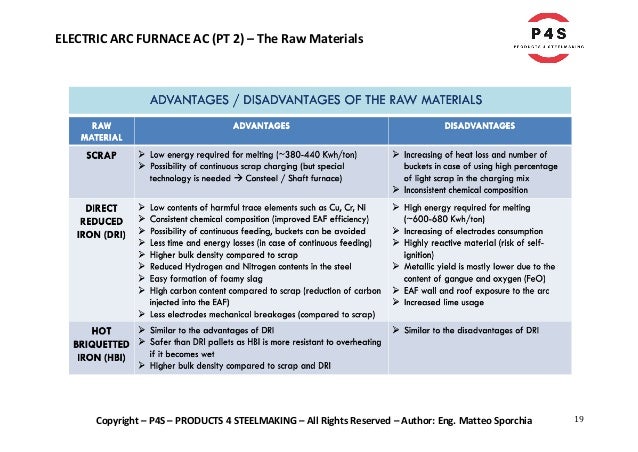

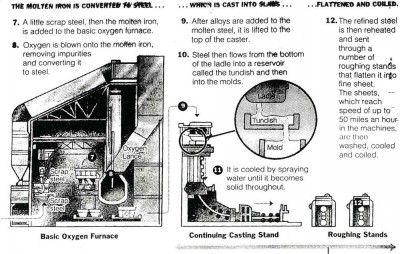

The first benefit is that the use of electric arc furnace allows steel to be made from a 100 scrap metal feedstock.

The first benefit is that the use of electric arc furnace allows steel to be made from a 100 scrap metal feedstock.

The advantages of primetals technologies electric arc furnaces.

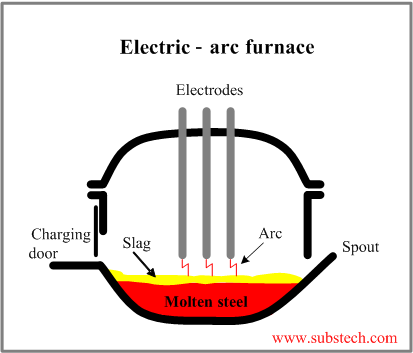

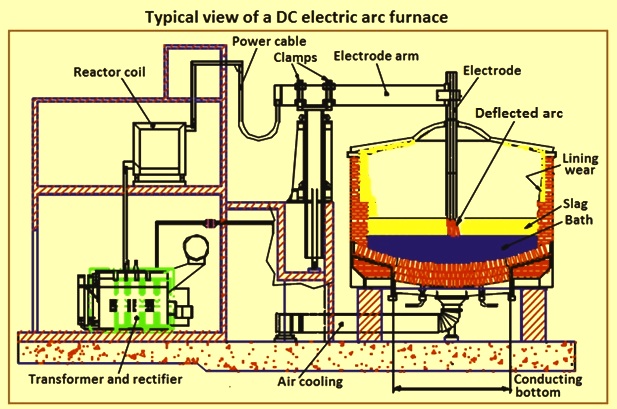

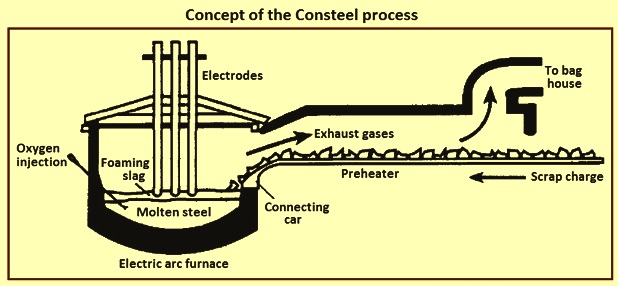

In electric arc furnace steelmaking the temperature of the slag is higher than that of the molten steel and the slag has a strong ability to participate in metallurgical reactions.

Advantages of electric arc furnace for steelmaking.

It comes with key advantages.

It is the technology that we envisage steelmakers will pursue in order to achieve carbon neutrality.

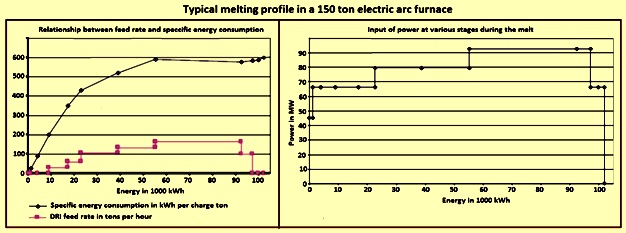

This greatly reduces the energy required to make steel when compared with primary steelmaking from ores.

See for example our eaf ultimate for maximum productivity flexible process control and high availability and our eaf quantum for the most efficient and environment friendly steelmaking.

A 100 scrap metal feedstock can be made into steel by the use of an electric arc furnace which can significantly reduce the required energy to make steel compared to primary steelmaking from ores.

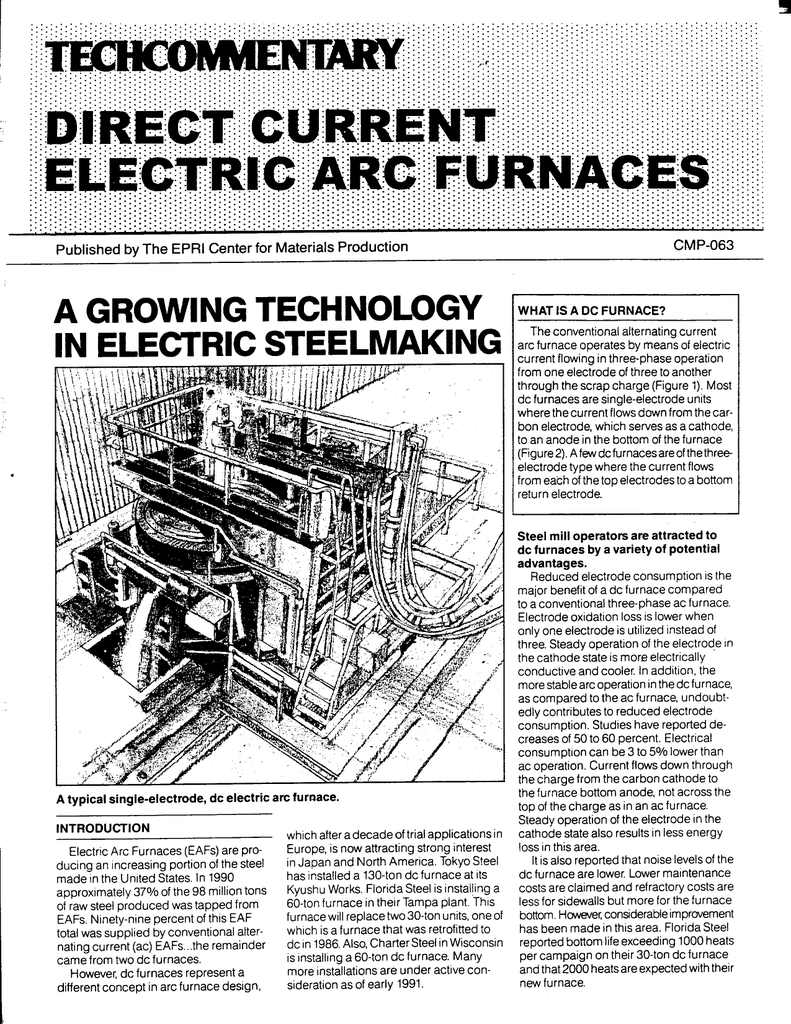

The arc can heat the furnace and the steel up to 4000 6000 directly and smelt special steels that contain refractory elements like w and mo.

In electric arc furnace steelmaking the temperature of the slag is higher than that of the molten steel and the slag has a strong ability to participate in metallurgical reactions.

That was followed by an additional 12 3 percent.

Flexibility is another benefit.

Eaf steelmaking production hit a new high in 2017 with a 7 5 percent year over year increase.

The arc furnace can also smelt various kinds of different steels compared with others the arc furnace also has several obvious advantages.

After holding at approximately 25 percent of global steelmaking production for about a decade through 2012 the migration to electric arc furnace eaf steelmaking accelerated during the past seven years.

In the induction furnace the slag is heated by molten steel and the temperature is low so the ability to participate in the metallurgical reaction is weak.

30 higher productivity than standard furnaces high yield efficiency with long electric arcs reduced specific losses using furnace heat to heat the scrap efficient use of burner systems to support the smelting process using a higher scrap pillar high productivity at low energy costs split bottom shell also available in our supply scope is a two part bottom shell.

This greatly reduces the energy required to make steel when compared with primary steelmaking from ores.

We know those blast furnaces cannot change its production very often.

H 2 based shaft furnace direct reduction is ready to use and can be introduced step by step into brownfield plants.

.jpg)