Step 1 check clamping pressure by clamping test strips in the brake approximately 3 or 4 inches away from each end of the brake.

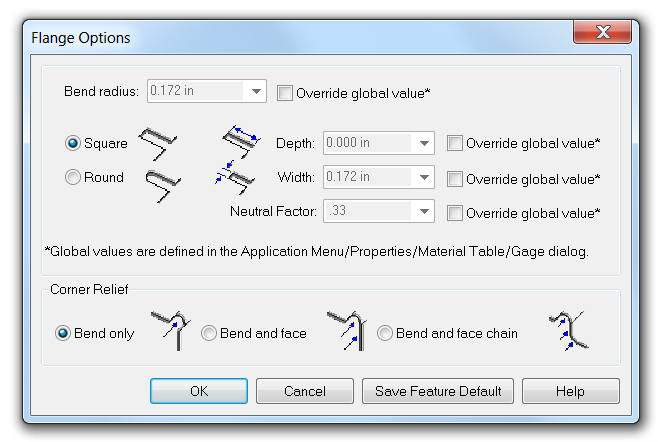

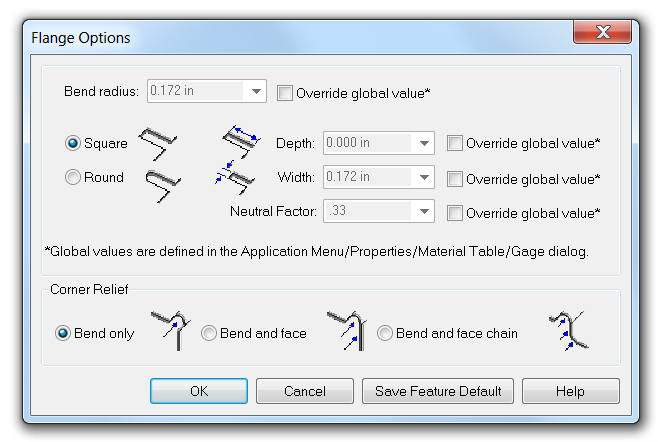

Adjust bend radius sheet metal brake.

In fact press brakes are more flexible and can bend certain parts that the folder just cannot do.

My question is this distance adjustment used to vary the bend radius rely that the material in the bend area will naturally form a regular circular bend though there is no support.

Additionally the clamp height has to be adjusted for the combined thickness of the sheet and the bar.

Sheet metal bends and brakes 09 29 2017 05 00 pm.

Oil apron pins clamping cams vertical guides behind the clamp frequently.

Wipe bending or edge bending is another way to bend sheet metal edges.

On some leaf brakes the radius can be somewhat controlled in the setup with set back.

The stroke depth will dictate the bend angle.

You won t be bending anything much thicker than 040 on a cheap er i mean inexpensive brake.

It is important to make sure that the sheet is properly pushed onto the wipe die.

This is probably a beginner question but here goes.

Set clamping pressure to zero or almost none and radius set back to at least 1 5 times material thickness when forming 18ga and 2 3 times for 16ga or heavier.

The worker can adjust the stroke depth on the machine.

The slack between the wipe die and the punch plays an important role in getting a good result.

As a user you should allow the adequate opening of the bottom die.

I usually just bend thinner sheets to get the desired radius then bend my part.

It would be best if you also took into accounts the bend radius and the material thickness.

At least adjust your brake for the heaviest material you use and leave it there for the lighter material too.

3 adjust the hydraulic sheet bending machine work mode to the jog adjustment state remove the upper and lower mold and other accessories make the mechanical block to the highest position off the coupling on mechanical block drive shaft gear.

The brake must be adjusted so that the fingers are set back from the edge by an amount equal to the radius of the tube plus the thickness of the material you are bending.

Use test strips of metal approximately 3 inches by 3 inches each of the thickness you will be forming for the following adjustments.

The bend radius will get defined by the profile of the punch.

However if folder radii do not work for you we can manufacture parts using our press brakes.

Geometry of tooling imposes a minimum bend dimension.

When bending thin material a radius former is usually used.